Sapele - Characteristics and Uses After centuries of non-stop exploitation, the worldwide market only recently came to terms that legendary Mahogany cannot constantly be harvested like in the old days, which opened a place for a new contender to enter into widespread use. Countless years of irresponsible forestry management have brought into question the sustainability of not only Mahogany, but several other North and South American species who have all landed under government protection and complete oversight of the commercial exploitation. After a quick period of adaptation, both large industrial and small-scale wood-processing artisans came to the realization that a viable alternative to Genuine Mahogany can be found in the much cheaper and readily available wood species Sapele. This African species had many similarities with more costly Genuine Mahogany, making it perfect substitution for its numerous exterior and interior applications. Sapele (also known as Entandrophragma cylindricum) shares thesame botanical family as the famed American and African Mahogany, making it a very close match in both visual appeal, wood processing, and working characteristics . While sapele is not directly a cousin of Mahogany, like Swietenia and Khaya trees are, it is still a part of the Entandrophragma genus of Meliaceae family that all these trees are part of. Because of this, the claims that Sapele is a close cousin of Mahogany are somewhat valid. Sapele originates from West Africa, and it can be most easily found in countries such as Tanzania, Nigeria, and Ghana where the individual trees can grow up to impressive height of 45 meters in the air (with some rare examples going up to 60 meters), with the trunk diameter that can almost reach 2 meters (6 feet). It is a deciduous tree only during a dry season in the West Africa, with leaves that can grow up to 10 centimeters in size. Since a lot of Sapele trees prefer to grow quite close to each other, they usually become very starved for sunlight. This has pushed this species of trees to grow quite large, with extensive canopy being formed only in the top one-fifth of their height. The tree is perfect for the creation of long plans since its main trunk section between the roots and canopy is impressively long, straight and without any side-branches that would compromise the integrity of the heartwood. The tree also grows small flowers that are 5mm in diameter with five yellowish petals surrounding it. However, these flowers grow only when the tree is leafless. Fruit that develops in these flowers takes the form of a pendulous capsule that is 4 centimeters wide and 10 centimeters long . When mature, this pod splits into five sections, each with 15-20 seeds inside of them. Today, Sapele is still readily available for purchase at a much cheaper level than Mahogany, in both lumber and veneer form. Because of its increased popularity and regular use as a substitute for Mahogany, this wood type is sometimes referred today as “ Sapele Mahogany.”

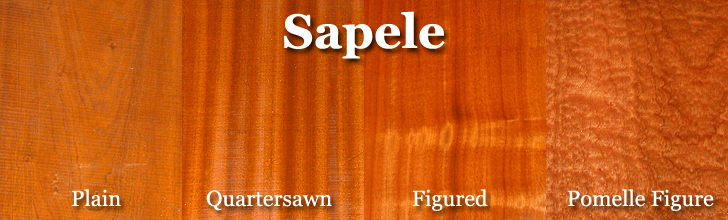

What is Sapele Wood? Sapele Wood has many characteristics that resemble Mahogany, most notably in the color of its heartwood ( golden to dark reddish brown, darkens with age if not treated with finishing oils that will prevent oxidation),grain patterns, and internal characteristics that make it very durable. One of the defining characteristics of Sapele is the interlocking grain patterns. These patterns are created from the fiber cells that stretch all the way from the lowest points in the roots all the way to the top of the canopy. During growth, these cells rotate in one way, and can often suddenly switch the direction of rotation once or several times. This interlocked grain patterns can not only cause various issues during woodworking, but it also has an impact on the visual appearance with the presence of ribbon stripes and many other dramatic figures on quartered sawn lumber and veneer. All theseanomalies in the texture of the wood create a dramatic and exotic look that is one of the primary reasons why Sapele and its more famous cousin Mahogany are so praised all around the world. The three most common textures of Sapele are Plain, Figured and Pommele Figure . In woodworking and cutting, these same interlocked grain patterns can cause severe tearouts. Thankfully, after hard work of cutting and molding, sapele readily accepts finishes and polishes. Itcan be polished to a very high luster. Sapele also takes nails, screws, and glues well, making it versatile and usable in construction many types of indoor and outdoor objects, including high-end wooden objects such as musical instruments, decorative furniture, turned objects and specialty items. One of the most common use case scenarios for sapele is indoors, windows, floor, and paneling. Supplies of Sapele were plentiful, but in recent years after increased exploitation that was caused by the lockdown on Mahogany trading, even Sapele is starting to get vulnerable. While the large-scale operations of replanting large quantities of Sapele trees are underway, the global stock of this type of lumber is starting to get limited. It is still very much readily available for purchase, but its price has already started to climb at a regular pace. Origins Sapele (also known also as aboudikro, saplewood, sapelli and Sapele Mahogany) is one of the largest trees that are native to the regions of tropical Africa. As a part of the genus Entandrophragma and the family of Meliaceae, it can be commonly found in rainforests of Ivory Coast, Ghana, Nigeria, Cameroon, Uganda, Tanzania, and others. In addition to rainforests, it can also be found in different forest types, such as evergreen, deciduous and transitional zones. Its full latin name is Entandrophragma cylindricum. Characteristics Tree size - 100-150 ft (30-45 m) tall Trunk diameter - 3-5 ft (1-1.5 m) Janka Hardness - 1,410 lbf (6,280 N) Average Dried Weight - 42 lbs/ft3 (670 kg/m3) Specific Gravity (Basic, 12% MC) - .50, .67 Crushing Strength - 8,750 lbf/in2 (60.4 MPa) Modulus of Rupture - 15,930 lbf/in2 (109.9 MPa) Elastic Modulus - 1,746,000 lbf/in2 (12.04 GPa) Shrinkage: Radial - 4.8%, Tangential: 7.2%, Volumetric: 12.8%, T/R Ratio: 1.5 Odor - Odorless while finished. Cedar-like scent during woodworking. Workability - Problematic during machine operations, with a high chance of interlocked grain tearouts during cutting. The surface of the wood reacts strongly when in contact with iron, causing the appearance of stains and discoloration. Tools are moderately blunted during cutting, but the wood takes nails, screws, glue and finishes quite well. Texture - Uniform and very fine texture, which can take great natural luster. Grain - Wavy and interlocked grain. Sustainability - Placed on IUCN Red List and marked as Vulnerable for loss of 20% of the population in past three generations. The tree is experiencing large exploitation and decline in natural growing range. Required growth density - No specific requirements for growth density Drying - Medium. The stability and durability of sapele are very dependent on its being dried properly. Part of drying is done in harvest zones in Africa, while the final air drying procedure is done in large commerce zones of Europe, US and Asia until the moisture content reach 6 to 8 percent. Durability - Medium. Can survive long with proper finishing, average immunity against rot and insects. Maintenance - Low Cost - Affordable, but with raising cost due to new limits on commercial exploitation. Uses After a reduction in the availability of South American Mahogany, Sapele became a wood of choice for various woodworking projects that demand the use of high-quality and visually appealing wood. Here is where Sapele can be most commonly found today: Fine furniture Cabinetry Doors and windows Musical instruments Architectural Millwork Turned objects Boatbuilding Various outdoor construction Indoor construction elements (beams) Countertops Flooring Paneling Veneer Various specialty items